| |

| Calibration Procedure For Dead Weight Tester |

|

| |

| (A) Check followings before

calibration of Dead Weight Tester |

| |

| Check for any

physical damage in dead weight tester.

Weight should not be damage or seriously

corroded. Make sure there is no dirt in

oil. The fall of piston should not be

apparently greater to make use of the

DWT difficult. The DWT can not be make

to operate satisfactorily due to wear or

damage to pump, piping, valve, O-rings &

seals. |

| |

| (B) Calibration of Dead Weight

Tester |

| |

|

|

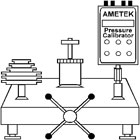

Recommended

calibration reference temp. is

27 + 5 'C and relative humidity

not more than 85 % RH.

Calibration area should be

adequately free from dust, shock

and vibration. DWT is calibrated

with using Digital Pressure

Calibrator. (Digital Precision

Pressure Calibrator AMETEK -

JOFRA INSTRUMEMT, DENMARK. +

0.05 / 0.1 % FS accuracy). Mark

Sr. No. on all weights for

separate identification. Check

there is sufficient oil in oil

reservoir. Level the DWT on

strong table base using spirit

level. |

|

| |

| Make sure there is no air in the hydraulic system. Connect digital pressure calibrator using suitable adopter on DWT as shown in figure. Apply different pressure in the system till the weight is lifted for certain level. Rotate lifted weight slowly & take pressure reading for all different weights. Tabulate the readings as under and find the % accuracy of DWT. |

| |

| DWT Weight

Used |

Pressure in

DWT Under Test in (A) in Kg /

cm2 |

Reading in Digital Master Pressure Gauge 35/200/700/1000 Bar (B) in Kg/cm2 |

Error

(A-B) in Kg/cm2 |

Accuracy in %

of Span

(A-B) / Spam *100 |

|

| |

| |

| Calibration

Procedure For Pressure Gauge |

|

| |

| (A) Check followings before

calibration of Pressure Gauge |

| |

| Check for any physical damage in

pressure gauge. Make sure there is no

restriction or choking in gauge input

connection. There should not be any

loose parts inside the pressure gauge.

All mounting screws should be fully

tight. |

| |

| (B) Calibration of Dead Pressure

Gauge |

| |

|

|

Recommended

calibration reference temp. is

27 ± 5 'C and relative humidity

not more than 85% RH.

Calibration area should be

adequately free from dust, shock

and vibration. Accuracy ratio of

master gauge and gauge under

test should be 3, 5 or 10 times

higher depending upon

availability and required

calibration standard. Care

should be taken for oxygen

service pressure gauges (Use no

oil). Pressure gauge is

calibrated with using comparison

test pump and master pressure

gauge. (Digital Precision

Pressure Calibrator. AMETEK

JOFRA INSTRUMENT,DENMARK. + 0.05

/ 0.1 % FS accuracy. |

|

| |

| Connect pressure gauge using

suitable adopters on the comparison test

pump as shown in figure. Make sure there

is no air in hydraulic system. Adjust

pointer at zero in the pressure gauge

under test at no pressure in the system.

Apply full scale pressure and check

maximum indication in the pressure gauge

under test, If not adjust the span in

pressure gauge. Repeat zero and span

adjustment till both shows ok. Apply

different pressure using manual screw

pump of comparator. Take 5 to 8 readings

for different value of pressure in

increasing and decreasing order.

Tabulate the reading as under and find

out % accuracy of the pressure gauge. |

| |

Reading in gauge

under test

(X) t in

Kg/cm2 |

Master Gauge

Reading (Y) in

Kg / cm2 |

Error

(X - Y) in Kg / cm2 |

Accuracy in % of span

(X - Y)/span x 100 |

| Up Scale |

Dn Scale |

Up Scale |

Dn Scale |

Up Scale |

Dn Scale |

|

| |